Welcome to the fascinating world of fruit ripening! Have you ever wondered how that green, unripe banana or avocado transforms into a perfectly ripe and delicious treat? Well, it all comes down to the science behind ethylene. Ethylene is a natural plant hormone that plays a crucial role in the ripening process of fruits. In this guide, we will take a deep dive into the science behind fruit ripening with ethylene, giving you a comprehensive understanding of this complex process. From the production and release of ethylene to its effects on fruit ripening, we will explore the intricate mechanisms that occur to ensure your favourite fruits are at their peak of flavour and nutritional value. This guide will equip you with the knowledge to understand ethylene ripening and how to use it effectively for commercial fruit ripening. So, let’s embark on this enlightening journey and unravel the secrets behind the transformation of green to golden!

The Role of Ethylene in Fruit Ripening

Fruit ripening is a complex process that involves various biochemical and physiological changes. Ethylene acts as a signal molecule that triggers and coordinates these changes. It is produced in various parts of the plant, including the fruit itself, and is responsible for the initiation, promotion, and coordination of the ripening process. Ethylene can influence a wide range of ripening-related events, such as softening of the fruit, color development, aroma production, and changes in flavor and texture. It also affects the synthesis of other hormones and enzymes involved in ripening.

Factors Affecting Ethylene Production

The production of ethylene in fruits is influenced by various factors, including temperature, oxygen levels, and hormonal regulation. For example, as fruits ripen, they produce more ethylene, leading to an increase in the ripening process. However, the production of ethylene can also be influenced by external factors, such as exposure to other fruits or the presence of stressors like pathogens or physical damage.

One of the key factors is temperature. Higher temperatures generally promote ethylene production, while lower temperatures can inhibit it. Oxygen levels also play a role, as ethylene production is reduced in low-oxygen environments.

Additionally, the presence of other fruits or plant parts can influence ethylene production. Fruits that are already ripe or undergoing ripening produce ethylene, which can accelerate the ripening process in neighbouring fruits. Furthermore, stressors like physical damage or pathogen infection can stimulate ethylene production as a defence mechanism.

Understanding these factors is crucial for post-harvest management and the control of fruit ripening.

The Stages of Fruit Ripening

Fruit ripening can be divided into several stages, each characterized by specific physiological and biochemical changes. The stages include the pre-ripening stage, the climacteric stage, and the post-climacteric stage.

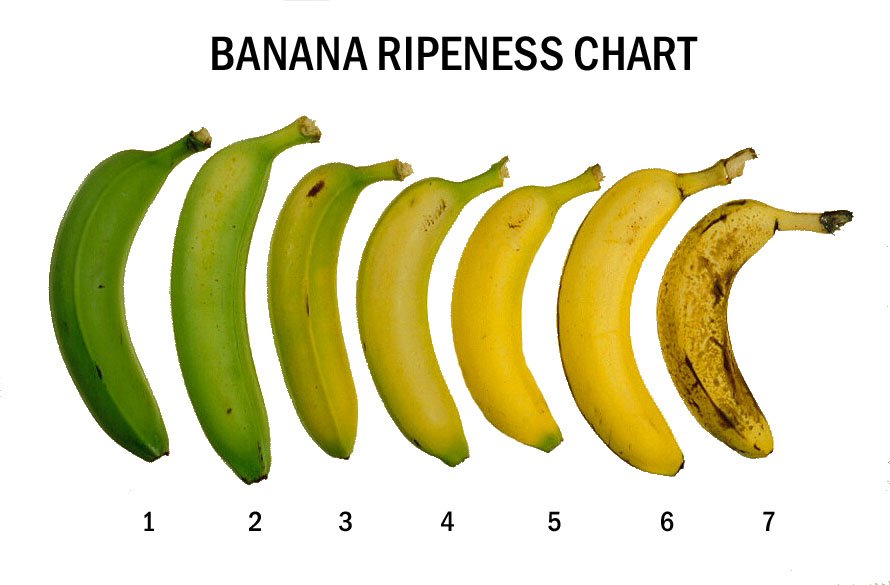

During the pre-ripening stage, the fruit is still green and firm. Ethylene production is low, and the fruit is not yet ready for consumption. However, as the fruit enters the climacteric stage, ethylene production increases significantly, and various ripening processes are initiated. This is the stage where fruits undergo significant changes in color, flavor, aroma, and texture.

Once the climacteric stage is complete, the fruit enters the post-climacteric stage. Ethylene production decreases, and the fruit becomes less responsive to ethylene. At this stage, the fruit may still undergo some changes, but at a slower rate compared to the climacteric stage.

Ethylene Detection and Measurement Methods

Detecting and measuring ethylene levels is crucial for understanding the ripening process and managing fruit quality. Various methods are available for ethylene detection, including gas chromatography, electrochemical sensors, and optical sensors.

Semiconductor, Electro-chemical sensors and optical sensors offer real-time monitoring capabilities and can be used in non-destructive measurements. These methods provide valuable insights into ethylene production and can help optimize fruit ripening conditions.

Effects of Ethylene on Fruit Quality and Shelf Life

Ethylene has both positive and negative effects on fruit quality and shelf life. On one hand, it promotes the ripening process and enhances the flavor, aroma, and color of fruits. On the other hand, it can lead to over-ripening, softening, and decay if not properly controlled.

Exposure to high levels of ethylene can accelerate the ripening process and shorten the shelf life of fruits. This is why it is important to manage ethylene levels during storage and transportation to maximize fruit quality and extend shelf life.

Controlling Fruit Ripening with Ethylene

Controlling fruit ripening with ethylene is a common practice in the fruit industry. Ethylene can be used to initiate and synchronize the ripening process, ensuring that fruits are ready for market at the desired stage of ripeness.

Various techniques are used to control fruit ripening with ethylene, including the use of ethylene generators, ethylene inhibitors, and controlled atmosphere storage. Ethylene generators release controlled amounts of ethylene, allowing for natural and uniform ripening. Ethylene inhibitors, on the other hand, can be used to delay the ripening process and extend shelf life.

Ethylene and Post-Harvest Management Techniques

Post-harvest management techniques play a crucial role in maintaining fruit quality and extending shelf life. Proper handling, storage, and transportation practices can minimize ethylene exposure and prevent premature ripening and decay.

A Cold room is commonly used to slow down the ripening process and extend the shelf life of fruits. Modified atmosphere packaging, which involves controlling oxygen and carbon dioxide levels, can also help maintain fruit quality by reducing ethylene production and inhibiting the growth of spoilage-causing microorganisms. Ethylene absorbers and scrubbers are also widely used in order to control and maintain minimum ethylene level during storage and transportation.

Using Ripe All Ethylene Generators for Natural, Quick, and Optimal Fruit Ripening

Ripe All Ethylene generators and Mini Ripe Ethylene Generators are widely used in the fruit industry to achieve natural, quick, and optimal ripening. These generators release ethylene gas in controlled amounts, allowing for consistent and uniform ripening across a batch of fruits. The use of ethylene generators offers several advantages, including reduced labor costs, improved fruit quality, and increased efficiency. By using ethylene generators, fruit producers and suppliers can ensure that their products reach consumers at the peak of flavor and nutritional value.

Ripe All Ethylene Generator is a catalytic generator used for chemical-free ripening of climacteric fruits like banana, mango, avocado, papaya, tomato etc. Unlike other generators, this revolutionary device has features like 4G sim connectivity for direct messaging updates to users. It also boasts of a backup heater mechanism which turns on automatically during primary heater failure. This single generator can be used for ripening of all climacteric fruits without the need of buying multiple generators for different fruits.

Another cost effective banana ripening machine manufactured by HundredX Agritech is Mini Ripe Ethylene generator. This ethylene generator’s price is very economical and easy on pocket without compromising quality. This low maintenance generator is easy to service, wall mounted and has a lightweight robust steel body.

By harnessing the power of ethylene, fruit producers and ripeners can deliver perfectly ripened fruits that are a delight to consumers worldwide. So, let’s embrace the science behind fruit ripening and unlock the secrets behind the transformation of green to golden!

Pingback: The Science Behind Fruit Ripening