From Green to Red: 5 Step guide on Tomato ripening using catalytic ethylene generators

Are your tomatoes taking forever to ripen? Don’t fret! We have the perfect solution for you. In this step-by-step guide, we will discuss tomato ripening using innovative and efficient catalytic ethylene generators by HundredX Agritech.

Catalytic ethylene generators offer a fast way when it comes to accelerating the ripening process. They release controlled amount of ethylene gas, a natural hormone that triggers the ripening of fruits, including tomatoes. The process is fairly simple and very effective. Since ethylene generators produce ethylene gas using catalytic conversion, they are also called catalytic ethylene generators.

Table of Contents

Understanding the tomato ripening process

Tomatoes are a fascinating fruit (yes, fruit!) that undergo a complex ripening process. This process is driven by the production and action of a natural plant hormone called ethylene. Ethylene is a colorless gas that plays a crucial role in the maturation and senescence of many fruits, including tomatoes.

As tomatoes develop on the vine, they initially produce low levels of ethylene. This low ethylene concentration allows the fruit to remain firm and green. However, as the tomatoes approach full maturity, their ethylene production increases dramatically. This surge in ethylene triggers a cascade of physiological changes that transform the tomatoes from firm and green to soft, juicy, and their characteristic vibrant red color.

The tomato ripening process involves a series of complex biochemical reactions. Ethylene stimulates the activation of enzymes that break down the cell walls and starch molecules within the tomato. This breakdown of structural components leads to the softening of the fruit and the development of its signature juicy, sweet, and tangy flavors. Additionally, ethylene triggers the production of carotenoids, which are responsible for the rich red pigmentation of ripe tomatoes.

Why ripen tomatoes using catalytic ethylene generators?

While tomato ripening will naturally occur on the vine, there are several reasons why using ethylene generators can be a beneficial approach. Firstly, it allows for greater control over the ripening process. By introducing a controlled amount of ethylene gas, you can synchronize the ripening of your tomatoes, ensuring a consistent and predictable harvest.

Another advantage of using ethylene generators is the ability to ripen tomatoes off the vine. This can be particularly useful for gardeners or small-scale farmers who may have a surplus of green tomatoes at the end of the growing season. By artificially ripening these tomatoes, you can extend the harvest and maximize your yield, reducing food waste and increasing the overall productivity of your tomato crop.

Furthermore, ethylene generators offer a more efficient and environmentally friendly alternative to traditional ripening methods.These generators release a controlled and targeted amount of ethylene, minimizing waste and ensuring a more precise and consistent ripening process. This can lead to higher-quality tomatoes with better flavor, texture, and appearance, making them more appealing to consumers and potentially increasing your profitability.

Why catalytic ethylene generator is a better option than other methods?

Tomato ripening steps using catalytic ethylene generator

Step 1: Selecting the right tomatoes for ripening

The first step in successfully ripening tomatoes using catalytic ethylene generators is to select the appropriate tomatoes. Ideally, you want to choose tomatoes that are at the mature green stage, meaning they have reached their full size but have not yet begun to change color.

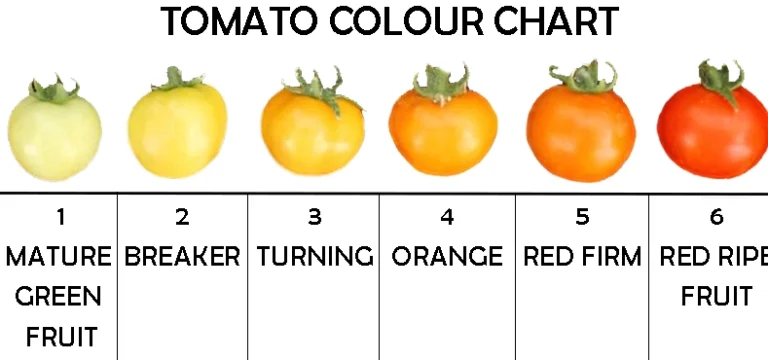

According to the USDA, tomatoes go through six color stages: green, breakers, turning, pink, light red, and red. Green tomatoes are the least ripe, while those displaying yellow, pink, or red hues are considered to be in the ‘breaking’ stage.”

Mature green tomatoes are the most responsive to the application of ethylene gas, as they have the necessary physiological and biochemical mechanisms in place to undergo the ripening process. Avoid using tomatoes that are already starting to show signs of color change, as they may have already begun the natural ripening process and may not respond as well to the additional ethylene exposure.

When selecting your tomatoes, look for fruits that are free from blemishes, bruises, or other physical damage. Damaged tomatoes are more susceptible to spoilage and may not ripen as evenly as their undamaged counterparts. Always try to choose tomatoes that are similar in size and maturity level, as this will ensure a more uniform ripening outcome.

Step 2: Stacking the tomatoes for ripening in a ripening room

Once the tomatoes are placed in boxes or crates, they need to be transferred to the temperature controlled ripening room. Ensure that the crates are stacked and spaced out evenly, allowing for good air circulation around them. The temperature should be 20 Deg C to 24 Deg C depending upon the variety.

Step 3: Setting up the catalytic ethylene generator

The next step is to set up the generator in the ripening room. The generator should be placed in a strategic location that ensures the even distribution of the ethylene gas throughout the space. Depending on the size of your ripening setup, you may need to use multiple generators to achieve the desired ethylene concentration. Consult the manufacturer’s instructions for guidance on the appropriate placement and number of generators required for your specific needs.

Once the generator(s) are in place, you’ll need to ensure that the ripening concentrate is filled in the generator’s tank. Follow the manufacturer’s instructions carefully to ensure the correct dosage and to avoid any potential safety hazards.

After the generator is set up and switched on, the door is closed to maintain the desired ethylene concentration. A dedicated ripening room is preferable, or any other suitable setup that can be effectively sealed off from the outside environment to maintain the desired temperature.

Step 4: Monitoring the ripening process

As the tomatoes begin to ripen, it’s important to closely monitor the process to ensure optimal results. Regularly check the tomatoes for signs of color change, softening, and overall development. This will allow you to adjust the ripening parameters as needed to achieve the desired level of ripeness.

Pay close attention to the temperature and humidity levels within the ripening environment, as these factors can significantly impact the rate of ripening. Consult the manufacturer’s recommendations or industry guidelines to ensure that the conditions are within the optimal range for tomato ripening.

You should make any necessary adjustments to the ethylene concentration or environmental conditions based on your observations time to time for better results.

Step 5: Ready for market

Once the tomatoes have reached the desired level of ripeness, it’s time to send them to market for sale. For longer-term storage, it’s important to note that refrigeration can sometimes impact the flavor and texture of tomatoes, so it’s best to use them within a week or two of storage. Alternatively, you can consider canning, freezing, or dehydrating the tomatoes to extend their shelf life and preserve their quality for future use.

Tips for successful tomato ripening using catalytic ethylene generators

-Ensure the ripening environment is clean and free from any contaminants or strong odors that could affect the tomatoes.

-Monitor the temperature and humidity levels closely, as these factors can significantly impact the ripening process.

-Avoid opening the ripening environment unnecessarily, as this can disrupt the ethylene concentration and slow down the ripening.

-Consider using a data logger or other monitoring device to track the temperature, humidity, and ethylene levels within the ripening environment.

-Experiment with different ethylene concentrations and exposure times to find the optimal settings for your specific tomato variety and growing conditions.

-Inspect the tomatoes for any signs of spoilage or disease, and remove any affected fruits immediately to prevent the spread of contamination.

-Stay up-to-date with the latest research and industry best practices for tomato ripening.

Conclusion

Tomato ripening using ethylene generators is a highly effective and efficient way to ensure a consistent, high-quality harvest. By understanding the science behind the ripening process and following the step-by-step guide outlined in this article, you can begin tomato ripening and get better results in less time.

Whether you’re a a small-scale farmer, or a commercial large scale ripener, our ethylene generators offer a valuable tool for maximizing your tomato yields and reducing food waste. By taking the time to properly select, prepare, and monitor your tomatoes during the ripening process, you can achieve the perfect balance of color, texture, and flavor that will delight your customers. Happy ripening!

Introducing Ripe All Ethylene Generators for natural, fast and optimal fruit ripening

Ripe All Ethylene generators and Mini Ripe Ethylene Generators are widely used in the fruit industry to achieve natural, quick, and optimal ripening. These generators release ethylene gas in controlled amounts, allowing for consistent and uniform ripening across a batch of fruits.

Ripe All Ethylene Generator is a catalytic generator used for the chemical-free ripening of climacteric fruits like banana, mango, avocado, papaya, tomato etc. Unlike other generators, this revolutionary device has features like 4G SIM connectivity for sending notifications to users. It also boasts of a backup heater mechanism which turns on automatically if the primary heater fails due to any reason. This generator can be fine-tuned for the ripening of all climacteric fruits without the need to buy multiple generators for different fruits.

Another cost-effective banana ripening machine manufactured by HundredX Agritech Pvt Ltd is the Mini Ripe Ethylene generator. This ethylene generator’s price is very economical and easy on the pocket without compromising quality. This low-maintenance generator is easy to service, wall-mounted and has a lightweight robust steel body.