Gas used for artificial ripening of fruits

Fruit ripening is a natural process that involves a series of physiological, biochemical, and molecular changes, making the fruit edible, palatable, and nutritious. However, to meet market demands and ensure fruits reach consumers in optimal condition, artificial ripening techniques are often employed.

In this article, we will explore the various types of artificial fruit ripening methods used by traders. We will also explore the benefits of using ethylene as a safe and effective solution for artificial fruit ripening.

Table of Contents

What is artificial ripening of fruits

Do you ever wonder why the fruit you buy at the grocery store always seems to ripen perfectly, almost as if it was picked at the peak of its flavor?

Fruit ripening is a complex biological process that involves a series of physio-chemical changes, which transform the fruit from being hard, green, and inedible to soft, sweet, and palatable. As the fruit matures, its cells undergo a series of changes. The cell walls become softer, the starch is converted to sugars, and the chlorophyll pigments are broken down, revealing the underlying carotenoid and anthocyanin pigments that give the fruit its vibrant colors. These changes not only make the fruit more appealing to consumers but also enhance its nutritional value, as the levels of vitamins, minerals, and antioxidants often increase during the ripening process.

The natural ripening process can take several days or even weeks, depending on the type of fruit, the growing conditions, and various other factors. However, in the modern food supply chain, where fruits need to be transported over long distances and meet the demands of consumers, the natural ripening process can often be too slow. This is where artificial ripening techniques come into play, allowing growers and distributors to accelerate the ripening process and ensure that fruits reach the market in optimal condition.

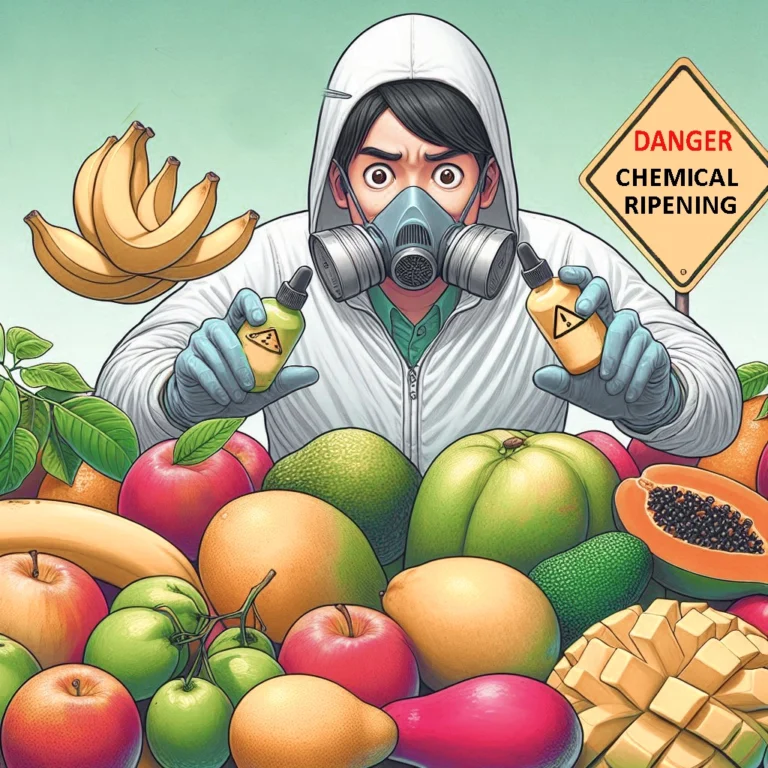

The dangers of using artificial ripening agents

While artificial ripening techniques can be effective in meeting market demands, they are not without their drawbacks. Some of the most commonly used artificial ripening agents, such as calcium carbide and ethephon, can be harmful to human health and the environment.

Calcium carbide, for example, is a cheap and readily available compound that is often used to ripen fruits like bananas, mangoes, and papayas. When exposed to moisture, calcium carbide releases acetylene gas, which can mimic the effects of ethylene and trigger the ripening process. However, the use of calcium carbide has been banned in many countries due to its potential health risks. Exposure to calcium carbide can cause skin irritation, eye damage, and even respiratory problems. Furthermore, the residues of calcium carbide can remain on the fruit’s surface, potentially contaminating the food supply.

Another commonly used artificial ripening agent is ethephon, a synthetic plant growth regulator that releases ethylene when it breaks down. While ethephon is generally considered safer than calcium carbide, it can still have adverse effects on human health and the environment. Exposure to ethephon can cause skin irritation, nausea, and headaches, and it has also been linked to reproductive and developmental issues in animal studies.

How ethylene works to ripen fruits naturally

In contrast to these artificial ripening agents, ethylene is a natural plant hormone that plays a crucial role in the fruit ripening process. Ethylene is a simple hydrocarbon gas that is produced by fruits and other plant tissues as they mature. When ethylene levels increase, it triggers a cascade of physiological and biochemical changes that lead to the ripening of the fruit.

The mechanism by which ethylene induces fruit ripening is well-understood. Ethylene binds to specific receptors on the fruit’s cells, which then activate a series of signaling pathways that regulate the expression of genes involved in the ripening process. These genes control the activity of enzymes that break down cell walls, convert starch to sugars, and degrade chlorophyll, among other changes.

By exposing fruits to controlled levels of ethylene, growers and distributors can effectively mimic the natural ripening process and ensure that the fruits reach the market at the optimal stage of ripeness. This is known as “ethylene-based” or “ethylene-assisted” ripening, and it is considered a more natural and environmentally friendly alternative to the use of other dangerous ripening agents.

The advantages of ethylene over other artificial ripening agents

Ethylene-based ripening offers several advantages over the use of other artificial ripening agents, such as calcium carbide and ethephon.

Firstly, ethylene is a naturally occurring plant hormone, and its use in fruit ripening is considered a more natural and sustainable approach. Unlike synthetic ripening agents, ethylene does not leave harmful residues on the fruit’s surface, making it a safer choice for both consumers and the environment.

Another key advantage of ethylene-based ripening is its precision and control. Growers and distributors can carefully regulate the concentration and duration of ethylene exposure through ethylene generator to achieve the desired level of ripeness. This ensures that the fruits reach the market in optimal condition. This level of control is not always possible with other artificial ripening agents, which can sometimes lead to uneven or over-ripening of the fruits.

Furthermore, the use of ethylene in fruit ripening has been extensively studied and is well-regulated in many countries. There are clear guidelines and safety protocols in place to ensure that ethylene is used in a safe and responsible manner, minimizing the risks to human health and the environment. This level of regulation and oversight is not always the case with other artificial ripening agents, which can sometimes be used without proper safety precautions.

Safety regulations and guidelines for using ethylene in fruit ripening

The use of ethylene in fruit ripening is subject to a range of safety regulations and guidelines, which are designed to ensure that the process is carried out in a safe and responsible manner. These regulations vary from country to country, but they generally cover aspects such as the proper storage and handling of ethylene, the correct dosage and exposure times, and the monitoring of residue levels on the final fruit products.

In India, the Food Safety and Standards Authority of India (FSSAI) prohibits the use of calcium carbide for artificial ripening due to its harmful effects, such as the presence of arsenic and phosphorus residues. Instead, FSSAI permits the use of ethylene gas up to 100-150 ppm as a safe ripening agent.

In the United States, the National Organic Standards Board (NOSB) permits to use ethylene gas to ripen organic fruits and vegetables. According to Rule 205.605(b), ethylene is allowed for post-harvest ripening of tropical fruits like bananas and citrus degreening. This regulation ensures that organic produce can be ripened safely and effectively while maintaining its organic certification standards.

The European Union has implemented strict regulations on the use of chemicals in food production, including the ripening of fruits. The European Commission Regulation (EC) No 889/2008 of 5 September 2008, detailed rules for the implementation of Council Regulation (EC) No 834/2007 on organic production and labelling of organic products with regard to organic production, labelling and control are mentioned.

These regulations ensure that the use of ethylene is subject to strict controls and that the final fruit products are safe for consumption.

Conclusion: Ethylene as a natural, sustainable and environmentally friendly solution

In conclusion, the use of ethylene in fruit ripening offers a safe, effective, and sustainable alternative to the use of synthetic ripening agents. As a naturally occurring plant hormone, ethylene triggers the natural ripening process in fruits, without the need for harmful chemicals or residues. The ability to precisely control the concentration and duration of ethylene exposure allows growers and distributors to optimize the ripening process and ensure that fruits reach the market in optimal condition.

Furthermore, the use of ethylene in fruit ripening is subject to strict safety regulations and guidelines, ensuring that the process is carried out in a responsible and environmentally friendly manner. The success stories of companies that have adopted ethylene-based ripening systems demonstrate the tangible benefits of this approach, including improved product quality, reduced waste, and a more sustainable supply chain.

Ethylene Generators for natural, fast and chemical-free fruit ripening

Ripe All Ethylene generators and Mini Ripe Ethylene Generators are widely used in the fruit industry to achieve natural, quick, and optimal ripening. These generators release ethylene gas in controlled amounts, allowing for consistent and uniform ripening across a batch of fruits.

Ripe All Ethylene Generator is a catalytic generator used for the chemical-free ripening of climacteric fruits like banana, mango, avocado, papaya, tomato etc. Unlike other generators, this revolutionary device has features like 4G SIM connectivity for sending notifications to users. It also boasts of a backup heater mechanism which turns on automatically if the primary heater fails due to any reason. This generator can be fine-tuned for the ripening of all climacteric fruits without the need to buy multiple generators for different fruits.

Another cost-effective banana ripening machine manufactured by HundredX Agritech Pvt Ltd is the Mini Ripe Ethylene generator. This ethylene generator’s price is very economical and easy on the pocket without compromising quality. This low-maintenance generator is easy to service, wall-mounted and has a lightweight robust steel body.